12V Lithium Ion Battery Recycling Charger Manufacturer

ABOUT

12V Lithium Ion Battery Recycling Charger Manufacturer

|

Warranty |

1year |

|

Anode Material |

LFP |

|

Chargeable |

YES |

|

Battery Type |

Prismatic |

|

Nominal Capacity |

12.8V |

|

Charge End Voltage |

14.6V |

|

Discahrge Cut-off Voltage |

10V |

|

Nominal Capacity |

100Ah |

|

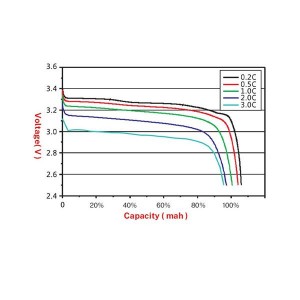

Max discharge current |

150A |

|

Max charge current |

100A@1C |

|

Cycle Life |

2000times |

|

Protection |

Over-charge |

|

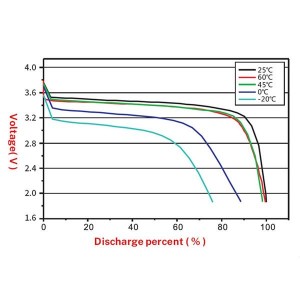

Operating Temperature |

-20℃~60℃ |

|

Components |

Battery Cell+BMS+battery case+connector |

|

Battery Size |

329*172*214mm |

Lithium battery is a new type of high-energy battery successfully developed in the 20th century. It can be understood as a battery containing lithium elements (including metal lithium, lithium alloys, lithium ions, lithium polymers), and can be divided into lithium metal batteries (very few production and use) and lithium-ion batteries (in large use today). Because of its high specific energy, high battery voltage, wide operating temperature range, long storage life, etc.

Basic working principle

When the battery is charged, the lithium-containing compound at the positive electrode has lithium ions released, and the lithium ions move to the negative electrode through the electrolyte. The carbon material of the negative electrode has a layered structure, and it has many micropores. Lithium ions that reach the negative electrode are embedded in the micropores of the carbon layer. The more lithium ions are embedded, the higher the charging capacity.

When the battery is discharged (that is, the process of using the battery), the lithium ions embedded in the carbon layer of the negative electrode come out and move back to the positive electrode. The more lithium ions returned to the positive electrode, the higher the discharge capacity. The battery capacity we usually refer to refers to the discharge capacity.

During the charging and discharging process of lithium-ion batteries, lithium ions are in a moving state from positive electrode → negative electrode → positive electrode. This is like a rocking chair, the two ends of the rocking chair are the two poles of the battery, and the lithium ions move back and forth between the two ends of the rocking chair. So lithium-ion batteries are also called rocking chair batteries.